Power tools buying guide

Power tools buying guide

Introduction

Home improvement and construction projects are made much easier when you have the right power tools. But, with so many different types of power tools available, how do you know which ones are right for your needs?

This power tool buying guide will help. It tells you everything you need to know about the most popular power tools. It covers what they are, how they work, the types available, and what to consider when buying each type. In addition, we look at power tool accessories, storage, and maintenance and highlight some general things to consider when purchasing power tools.

What is a Power Tool?

A power tool is a tool that operates with a power-driven motor (supplied by electricity, petrol, a battery or compressed air). The motor automatically drives a specific action in the power tool (depending on the type), exerting significantly more speed and force than is achievable through a manual tool. This means a power tool can make light work of any task it's intended for. As a result, jobs can be completed quickly and with a lot less effort, making power tools an essential part of a tool kit for tradespeople and DIYers alike.

There are many different types of power tools available, each with different considerations, which we’ll run through in the next section.

Types of Power Tool

The following sections cover the popular types of power tools used for various tasks and materials. There are power tools to suit every budget and skill level and for different home or work circumstances, such as whether you're working in one place or need the tool to be portable.

Corded vs cordless

Many power tools offer a corded and cordless option. Most corded power tools run on electricity, so they have a cord plugged into a socket. And a few corded power tools use compressed air, so they are attached to an air compressor via a hose. On the other hand, a cordless power tool is powered by petrol or a rechargeable battery, so it doesn't have a cord.

When deciding whether a corded or cordless power tool is best for you, consider the pros and cons below:

Corded power tool pros:

-

The most powerful corded power tools are cheaper than their cordless equivalents

-

They run for as long as you need them to without having to change batteries or add fuel

-

Their high power output lets you work on tough materials without any noticeable loss in performance

-

As there’s no heavy battery, they tend to be lighter than cordless models

Corded power tool cons:

-

Mobility is reduced The cord makes them unsuitable for working up a ladder or on scaffolding

-

There are more safety risks

Cordless power tool pros:

-

They are convenient

-

They give you greater mobility/portability than a corded power tool as you don’t need to be near a power supply

-

They are safer to use than a corded power tool

Cordless power tool cons:

-

The most powerful cordless power tools are more expensive than their corded equivalents

-

The battery life or fuel tank size limits how long they can be used each time

-

They are usually less powerful than their corded equivalents.

Brushed vs brushless

On power tools, the terms brushed and brushless refer to their motor type. Brushed power tools have a motor that’s driven by small metal brushes. Whereas brushless power tools have a motor with an electronic circuit board and sensor.

The absence of brushes means brushless motors experience less friction and heat build-up than brushed motors, making brushless power tools more efficient and powerful. As a result, power tools with brushless motors are more expensive, but they have a longer lifespan. So, they are cheaper in the long run, particularly if the tool gets heavy, frequent use.

Drills Explained

A drill is used to bore holes into materials. It can make light work of various tasks, from hanging mirrors and cabinets to putting up shelves and TV brackets. Depending on the type of drill you buy, they can drill through materials such as wood, plasterboard, brick, masonry, and even metal.

-

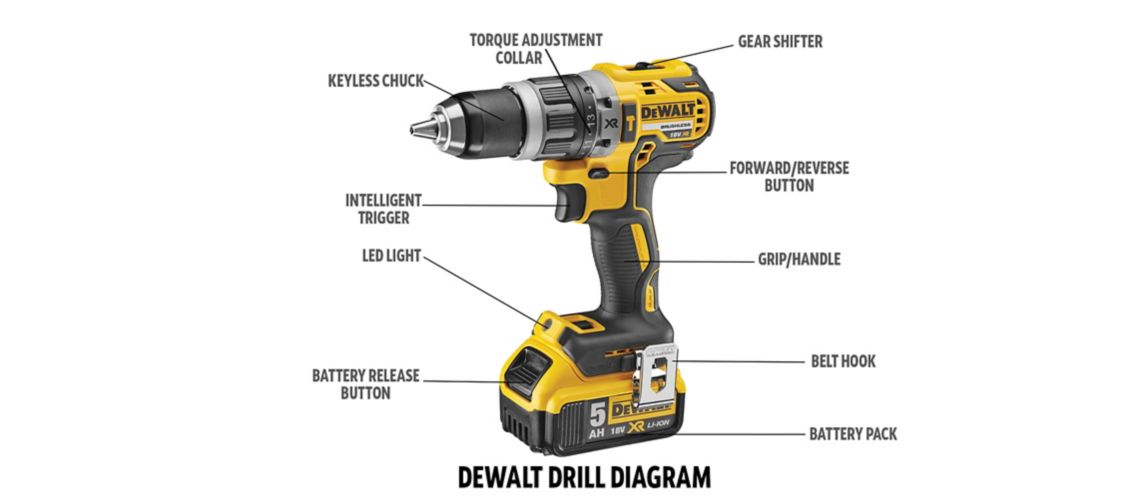

How drills work: The nose of a drill (called a chuck) holds a drill bit. When the trigger is pulled, an electric motor causes the chuck and drill bit to rotate at high speed. The drill bit cuts into the material it is being held against to create a hole.

-

Different types available: Each type of drill is suited to specific tasks and materials. For example, a drill driver is a drill and screwdriver in one. But for drilling holes in tough masonry materials, you'll need a hammer (SDS) or percussion drill. Or there's the combi drill which is a drill driver and hammer drill in one, making it an excellent allrounder drill.

-

Things to consider when buying a drill: What drilling tasks you'll need it for and what type of material you'll drill into. This will help you decide on the type of drill you need (i.e., drill driver, hammer, combi, etc.). Then consider how frequently you'll use the drill. Also, how portable do you need the drill to be, and therefore do you need a corded or cordless model?

Read our best drills buying guide for more help choosing the right drill for your needs.

Electric Screwdrivers Explained

An electric screwdriver drives screws into wood or pre-drilled holes in other materials. It's the perfect tool for putting together flatpack furniture or anything that uses screws.

-

How electric screwdrivers work: The nose of an electric screwdriver (called a chuck) holds a screwdriver bit. When the trigger is pulled, an electric motor causes the chuck and screwdriver bit to rotate at high speed, driving the screw into the material it's held against. Most electric screwdrivers also have a reverse function to remove screws. Electric screwdrivers rotate slower than drill drivers, making them the better tool when screws need to be driven with precision and care.

-

Different types available: There are three types of electric screwdrivers. First, a straight screwdriver has a straight handle and looks like a manual screwdriver. The second type is a pistol screwdriver, which resembles the shape of a drill. And finally, there is an electric screwdriver that holds and feeds screws as you work.

-

Top things to consider when buying an electric screwdriver: What you will need it for and whether it's for DIY or professional use. Straight electric screwdrivers suit DIYers looking to carry out light-duty screw-driving tasks. Pistol screwdrivers vary in power. Low-powered models are suitable for screwing into soft materials, whereas higher-powered models are better for screwing into harder materials. The screwdriver type that feeds screws as you work is designed for professional use.

Impact Drivers Explained

An impact driver drives fasteners, such as screws, nuts, and bolts into materials. Unlike an electric screwdriver or drill driver, it outputs high levels of torque, making it more efficient for quickly driving long, wide, and large screws into tough materials.

-

How impact drivers work: The nose of an impact driver (called a chuck) holds a screwdriver bit. When its trigger is pulled, the chuck and the screw bit rotate at high speed in a two-step-forward, one-step-back pattern. The rotation is combined with bursts of impact and high torque levels to drive in fasteners quickly.

-

Different types available: A standard impact driver and an impact wrench are the two main types. Other impact driver types include compact and ultra-compact versions of these two. The two types have different uses. For example, an impact driver uses hex-shaped screw bits to drive in screws, whereas an impact wrench uses square socket bits for fastening and loosening lug nuts and bolts.

-

Top things to consider when buying an impact driver: What type of fasteners do you need to drive, and what kind of material will you be driving the fasteners into? This will help you decide on the type of impact driver you need and its power and torque (the harder the material, the more power, and torque you need). Another thing to consider is how often you'll use it, and the power that’s needed. For more help choosing the right impact driver for your needs, read our impact driver buying guide.

Angle Grinders Explained

An angle grinder is used for grinding, cutting, polishing, and sanding various materials. But it can also be used for metalwork jobs such as removing rust, adding a matte finish to a shiny surface, and sharpening blades.

-

How angle grinders work: An angle grinder has a head that holds a disc. When its trigger is pulled, a motor rotates the disc at a very high speed. The disc is placed against the material, and it will grind, cut or polish, etc., depending on the type of disc being used.

-

Different types available: The most common types are the 115mm (4 ½”), 125mm (5”), and 230mm (9”). These sizes all refer to the size of the discs they take. The 115mm angle grinder is best used for precision and finishing work. The 125mm is suitable for regular, small-scale tasks. And the 230mm is used primarily in the construction industry. There are also air angle grinders which are powered by compressed air. They are mainly used by professional welders and metal workers.

-

Top things to consider when buying an angle grinder: The most important factor is the type of tasks you'll be using it for. This will influence the size you buy and its power rating. For example, a big angle grinder takes bigger discs to make deeper cuts than a smaller one. And a high-powered angle grinder is needed for working on dense materials. Also, consider whether you need the angle grinder to be portable, how long you'll need to run it in one period, and whether it's for infrequent DIY use or frequent professional use.

Read our angle grinder buying guide for more help choosing the right one for your needs.

Air Compressors Explained

An air compressor is a machine that converts atmospheric air into energy that's then used to power various tools and devices.

-

How air compressors work: By sucking in air through a pump, which then forces it into the storage tank, compressing it as it goes. The stored compressed air can then be used as power by attaching an air hose and air tool to the tank. When the trigger on the tool is pressed, pressurised air is released to power the tool.

-

Different types available: The main types are the belt drive and direct drive air compressors. The difference is in how their pumps are attached to the motor, which determines the airspeed and pressure they can output. A belt-drive air compressor's speed and pressure can be varied, while a direct drive air compressor can't.

-

Top things to consider when buying an air compressor: The most important factor is what tools and tasks you will use it for. That's because all air tools are given a standard cubic feet per minute (SCFM) rating, indicating the minimum amount of airflow they require to run, so the air compressor will need to output the same or more airflow as the rate required. You'll also need to consider how frequently and how long you'll use it to determine what air storage tank capacity you need and whether it needs to be portable.

For more help choosing a suitable air compressor for your needs, read our air compressor buying guide.

Nail Guns Explained

A nail gun is used to drive nails into tough materials in one swift, effortless action, vastly reducing the time and effort it takes to do the job manually with a hammer. It’s excellent for large-scale or repetitive nailing tasks such as laying decking or flooring, roofing, fencing, furniture making, etc.

-

How nail guns work: A nail gun has an inbuilt magazine that is loaded up with nails. When the gun’s trigger is pulled, it fires a nail into the material it’s aimed at. A new nail is then automatically loaded via a spring, which pushes the magazine up, allowing you to fire nails in quick succession.

-

Different types available: All nail guns can be split into two categories: first fix and second fix nail guns. First fix nail guns are designed to complete rough woodwork and construction jobs where the nails will be hidden. Second fix nail guns are designed to complete more refined 'finishing off' tasks where the nails are visible, such as furniture making, securing skirting boards, or door frames.

-

Top things to consider when buying a nail gun: The most important factor is what task you will use it for. This will determine the type and size of nails you need to drive and, therefore, the type of nail gun you need. Also, consider whether it needs to be portable and if it's for infrequent DIY use or frequent professional use. This will help you decide between a corded and cordless model and power type.

Read our nail gun buying guide for more help choosing the right one for your needs.

View our range of nail guns here

Power Saws Explained

A power saw makes light work of cutting through materials such as wood, plastic, metal, aluminium, and masonry, vastly reducing the time and effort it takes to do the job manually with a hand saw.

-

How power saws work: Depending on the type, power saws have a circular cutting disc or a cutting arm powered by a motor. When the power saw is on, the circular blade spins at high speed, or, in the case of a saw arm, the blade moves rapidly up and down or forwards and backward in a sawing motion to cut through materials.

-

Different types available: Saws with arms include jigsaws for cutting thin materials in straight lines and curves and reciprocating saws used for demolition work. Some popular types of power saws that use circular cutting discs are circular and table saws for cutting straight lines and mitre saws that cut angles.

-

Top things to consider when buying a power saw: The most important thing is what will it be used for? Consider the type of material you’ll be cutting and the kind of cut you want (i.e., straight lines, angles, curves, etc.). Plus, how often you'll use it. For example, if it's for infrequent DIY use, you probably won't need as much power as a tradesperson who will use the tool frequently.

For more help choosing the right power saw for your needs, read our power saw buying guide.

Welders Explained

A welder is a machine that uses a high-powered electrical current to heat and melt metal so that two pieces can be fused together. It can weld metals such as iron, stainless steel and aluminium.

-

How welders work: Different types of welders work slightly differently, but their basic function is the same. A cable and ground clamp attaches a metal workpiece to the welder. An electrode is also connected to the welder through another cable. When the welder is switched on, a strong electrical current is fed through them. The user places the electrode a few millimetres from the metal workpiece, completing an electrical circuit that creates an electrical arc (like a lightning bolt) between the electrode and base metal. The extremely hot arc melts the electrode and base metal, creating a pool of molten metal that forms the joint between the pieces of metal being joined.

-

Different types available: The three most popular types of welders are MIG, Arc, and TIG welders. MIG welders are best suited to beginners. Arc welders use rod electrodes and are suitable for use outside and indoors. They are used primarily to repair pipework and fabricate metal shapes. The TIG welder is more difficult to use and is therefore suited to professional welders.

-

Top things to consider when buying a welder: What type of metal do you need to weld and what is your skill level? A MIG or Arc welder is best for beginners; they can weld a relatively wide range of materials. However, an Arc welder can only weld to a thickness of 1/8" or above. TIG welders are suited to professionals and can weld a broader range of materials.

Read our welder buying guide for more help choosing the right one for your needs.

Polishers Explained

A polisher is used to give a shine to materials more efficiently than polishing by hand. So, what is a polisher used for? It can be used to apply wax or remove scratches on vehicles, or polish stone.

-

How polishers work: A polisher has a head that holds a polishing disc. When its trigger is pulled, a motor rotates the disc or moves it in circles (depending on the type) at a very high speed. The disc is placed against the material to be polished.

-

Different types available: An orbital polisher and a rotary polisher are the two main types. An orbital polisher moves the disc head in small circular movements, rather than the whole disc rotating as it does on a rotary polisher. People often ask, what is the best car polisher? Orbital polishers are most suited for cars because they work at slower speeds, so there is less chance of over-polishing and accidentally damaging the paint.

-

Top things to consider when buying a polisher: One of the main things to consider when buying a polisher is how fast you want to be able to work. For occasional DIY use, speed may not be as important as it is for a professional who will use the tool frequently. Also, consider how far you are from a power source, as there are corded or cordless polishers, and the lengths on the corded models vary. So, if you opt for a corded polisher, check the cord is long enough to comfortably reach the vehicle or stone you are working on.

Electric Planers Explained

An electric planer is used for shaving thin layers off wood, plywood, or any man-made boards. So, what is an electric planer used for? It's used for woodworking projects, such as trimming doors, shelves, and uneven joists and chamfering the corners of deck and stair posts and handrails. It can also be used to cut rebates into the wood to accommodate a pane of glass.

-

How electric planers work: An electric planer has two flat metal plates on the bottom, with a gap between them. A metal blade protrudes slightly from the gap. A motor is activated when the trigger switch is pulled on the planer. This causes the blade to rotate at very high speeds. The planer is pushed along the wood's edge, shaving a slither off as it goes.

-

Different types available: A standard hand-held planer is the most used type of planer available. But there is also a table-top planer, which is called a thicknesser. As well as planing, it’s also used to cut lengths of wood to a consistent thickness.

-

Top things to consider when buying an electric planer: The number of blades, the blade speed, and the cutting width and depth. Electric planers can have between two and five blades. The more blades it has, the easier and faster it will cut. Likewise, the quicker the blade speed, the faster it will cut. The planing width and depth will determine how much wood you can cut with each pass. So, if you are working on large pieces of wood or want to shave large pieces from it, a wide and deep cutting blade will help you get the job done quickly. Also, consider whether it needs to be portable and if it's for infrequent DIY use or frequent professional use. This will help you decide between a corded or cordless planers, and power type.

Sanders Explained

A sander is used to give a smooth, professional finish to various materials. They can be used to sand wood or remove varnish, paint, and rust from wood and metal.

-

How sanders work: All sanders have a base plate with sandpaper attached. When the trigger switch is pulled, a motor is activated, which causes the base plate to move at high speed. The type of movement depends on the type of sander. For example, some sanders have a disc that rotates, some base plates vibrate, and some have a continuous belt that moves round in one direction. The base plate is held against the material being sanded.

-

Different types available:

- An orbital sander is a sander with a rotating base plate. It's ideal for quickly removing varnish and paint.

- A drywall sander is a type of orbital sander specifically designed for sanding down drywall.

- A belt sander is used to sand down wood quickly, as is a sheet sander.

- A detail sander has a small triangular head to reach corners and tight spaces, so it's best suited to precision work.

- A disc sander is a table-top sander designed to remove large amounts of wood.

A common question people ask is what does a hook and loop sander mean? Hook and loop is simply the system used to attach the sandpaper to the base plate. It works like Velcro.

-

Top things to consider when buying a sander: What type of base plate do you need? Choose a rotating base plate for removing paint and varnish, a vibrating or belt base plate for quickly sanding wood, and a triangular-shaped base plate for getting into nooks and crannies. Also, consider the base plate size and speed. A large and fast base plate will get the job done quicker than a smaller, slower base plate but with less precision. Also, does it need to be portable, and is it for infrequent DIY use or frequent professional use. This will help you decide between electric sanders or cordless sanders and power types.

Power Tool Accessories

Most power tools need accessories to work, and most are consumable accessories that will need replacing as they wear out. For example:

- Drill bits for drills

- Screwdriver bits for electric screwdrivers and impact drivers

- Cutting discs for angle grinders for angle grinders

- Grinding discs for angle grinders

- Polishing discs

- Collated nails for nail guns

- Cutting blades for power saws

- Welding supplies for welders

- Planer blades for planers

- Sandpaper for sanders

Power Tool Storage and Maintenance

All power tools must be stored and maintained carefully to ensure they always run safely and perform well. Regular maintenance also increases their lifespan and reduces the risk of breakdowns.

When it comes to storage, all power tools should be kept in a dry place, protected from frost, ideally in their own carry case.

Maintenance varies for each tool type, but generally, you should clear any debris after each use and check all the moving parts for wear and tear. Most power tools will also need their moving parts to be oiled regularly.

For more detailed maintenance tips, read our buying guides for angle grinders, air compressors, nail guns, and welders.

Key Considerations When Buying a Power Tool

We’ve covered the top things to consider when buying each type of power tool above. But here are a few more general things to consider for all types of power tools.

-

What safety and protection do you need?

Most power tools come with risks, so it's important to consider each tool, what the risks might be and how you can protect yourself and others. For example, wear PPE such as gloves, goggles, dust masks, and protective clothing when using sharp tools or for those that produce dust or shoot out debris. Use RCD adaptors on electrical tools. And ensure your workspace is clean, uncluttered, and, in the case of welders, well ventilated. -

What size and what power do you need?

Always consider what power you need in a power tool, as high-powered tools usually cost more than their low powered equivalents. A low-powered model is best if the tool is intended for infrequent DIY use unless you need the extra power to get through tough materials. But if the power tool will be used professionally, high power may be preferable. -

What battery is needed?

If you've decided on a cordless power tool, check the battery capacity to determine how long it will run on a full charge. Battery capacity is measured in amp-hours (Ah), and the number tells you how many amps of electrical charge the battery can deliver in one hour. Cordless battery capacity can range from 1.5Ah to 12.0Ah. The higher the number, the longer you can use the power tool before it runs out. Also, check if the tool comes with a battery, as not all do. -

What features are needed?

Power tools come with various functions and features, and what's included as standard will vary between different models. So, always check the features that are possible for each type of power tool before buying to ensure you don't miss out on something that may be useful to you. -

Where will it be used and what is the frequency of use?

This is important to consider if you plan to use the power tool frequently, for long periods, or away from a power source. For frequent use, consider buying one with high power and a brushless motor that will last longer. If the tool will be used for long periods, choose one with an ergonomic design. Also, if you're considering a cordless drill for portability, consider the battery weight, as holding a heavy battery will be tiring.