Nails Buying Guide

Nails Buying Guide

Introduction

Nails are essential for completing many building and construction projects. But there are so many kinds of nails available that it can be hard to know which ones you need. We’re here to help.

This nail buying guide explains what nails are used for, the parts they’re made up of and how to choose the right nails for a job. It then explains nail sizes and looks at the different types of nails in detail and the safety equipment you need when using them. Finally, it highlights some key things to consider before buying and answers some frequently asked questions.

What are Nails Mainly Used For?

Nails are mainly used to hold two pieces of material together. For example, to join pieces of wood in carpentry and joinery projects, fix plasterboard to wooden battens, secure roofing felt and tiles to a roof, attach fascias and soffits to buildings, and much more. They are suitable for both DIY and professional use.

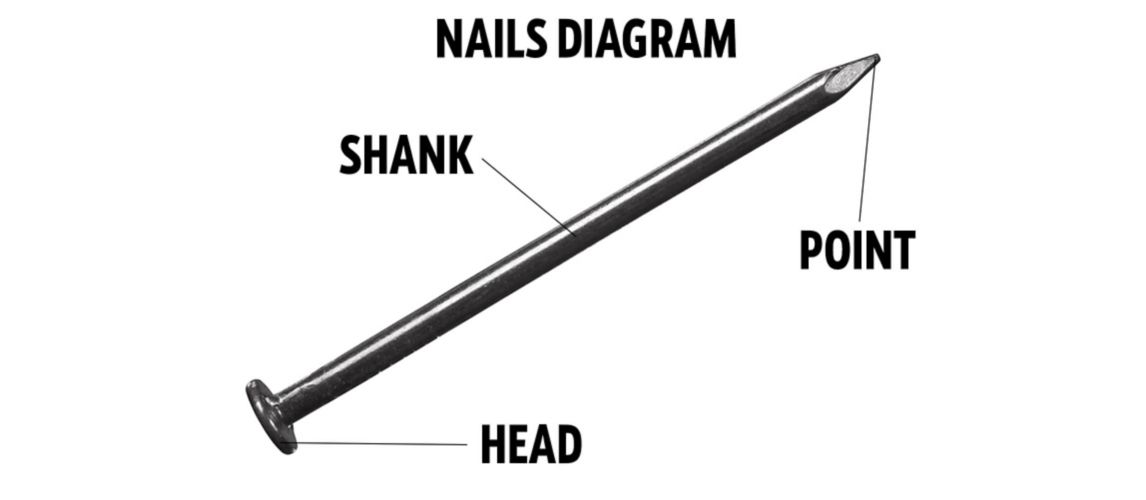

Parts of a Nail

All nails have three main parts:

A head - which is hit with a hammer to drive the nail into a material and prevent the nail from completely passing through. There are several nail head types available:

- A round head provides good contact with the hammer but leaves a rough finish.

- A flat head is round and large to reduce the risk of it passing through the material.

- A chequered head has a raised pattern on the surface to provide grip and prevent the hammer from slipping.

- A countersunk or capped head is small, allowing the head to be sunk slightly below the material’s surface so it’s less visible.

- A clipped head is used in nail guns.

A shank - which rests through the pieces of material to securely hold them together. There are several shank types available:

- A smooth shank drives through materials easily but doesn’t offer much resistance against being pulled out.

- A spiral shank has a spiral flute that rotates the nail as it’s being driven to give a more secure grip in hardwoods.

- A ring (or annular) shank has rings that lock with wood fibres to provide a good grip in softwoods.

A point - which is the tip of the nail that first pierces the material as the nail is driven in. There are two types of nail points:

- A diamond-shaped point makes nails easier to drive. Long diamond-shaped points also prevent the risk of materials splitting.

- A blunt point makes the nail harder to drive but gives even better protection against splitting the material.

How to Choose the Right Type of Nail

A vast selection of nails is available for a wide range of applications. They can be classified by the type of material they’re made from, such as: untreated steel, stainless steel, copper, zinc-plated and black phosphate, etc. Also, their size (diameter and length) and the different jobs and materials they can be used for.

The nails you choose will depend on the task. Things to consider are the type, thickness, density and strength of the substrate material, the size and weight of the load the nails need to hold, and the risk of the material tearing or splitting.

Nail Sizes Explained

There are many different nail sizes available to suit various tasks. Nail lengths are usually shown in millimetres, but sometimes the old-fashioned penny system is used. This was originally a way of showing how many English pennies it cost to buy 100 nails, shown as a number with the suffix D, but now it's an indication of nail length in inches. So, for example, a 10D nail's length is 3 inches, and 2D nails are 1 inch long.

The table below shows the correlation between the penny system and nail lengths in inches:

|

PENNY SIZE CLASSIFICATION |

NAIL SIZES IN INCHES |

|---|---|

|

2D nails |

1 inch |

|

3D nails |

1 ¼ inch |

|

4D nails |

1 ½ inch |

|

5D nails |

1 ¾ inch |

|

6D nails |

2 inches |

|

8D nails |

2 ½ inches |

|

10D nails |

3 inches |

|

12D nails |

3 ¼ inches |

|

16D nails |

3 ½ inches |

|

20D nails |

4 inches |

|

30D nails |

4 ½ inches |

|

40D nails |

5 inches |

|

60D nails |

6 inches |

Nail diameter refers to the diameter of the shank, not the head size. The shank diameter is also usually given in millimetres but can be given as a gauge size. Gauge sizes are measured using an imperial system that ranks the size with a number from 1 to 20. The higher the gauge, the wider the nail diameter.

Types of Nails

In this section, we list the popular types of nails that can be used for various jobs and materials for professionals and DIYers.

Bright nails explained

'Bright' is the term used to describe nails with no coating on top of the base material they're made from. For this reason, they're generally used for indoor joinery applications. However, bright nails made from stainless steel can be used outdoors because stainless steel is naturally rust-proof. In addition, bright nails are an ideal choice when the finished appearance is important, as the head can be punched below or very close to the surface, depending on the head type.

Bright nail types for wood include:

- Lost head nails and oval wire nails have small heads that can be hammered below the material’s surface. They are also less likely to split the wood, making them ideal for joinery and upholstery projects.

- Plain head wire nails are general-purpose nails suitable for multiple uses. However, they can often cause wood to split.

- Round wire nails have a full round head that sits on top of the material to clamp materials together securely.

- Annular ringshank nails have rings on their shank to give additional holding power and resistance against pulling out of the wood. They are used for projects where increased grip is needed, such as sub-flooring, where the extra grip can prevent floors from squeaking.

Other types of bright nails:

-

Polymer-header pins have a big head made from impact and UV-resistant polymer. They're used for fixing soffits, fascias, roofline trims, etc.

Materials and sizes they’re available in:

Bright nails are made from steel or stainless steel. They come in lengths ranging from 8 to 150mm, and diameters ranging from 2.36 to 6.4mm.

Top things to consider:

- When choosing between the different types of bright nails, consider how important the grip of the nail is. Annular ringshank nails provide the best grip, while lost head and oval wire nails are best for projects where grip isn’t so vital.

- If you need bright nails for an outdoor project, buy stainless steel, as they are the only type of bright nail suitable for external use.

Galvanised nails explained

Galvanised nails have a metal base material that's undergone a galvanising process, which involves hot dip coating them with a protective layer of zinc. As a result, they're highly resistant to rust and corrosion, which makes them ideal for outdoor projects.

Plasterboard nails are also galvanised, even though they are used indoors. They have large, round heads designed for countersinking for easy concealment and diamond-shaped points to reduce the risk of splitting wall studs.

Materials and sizes they’re available in:

Most galvanised nails are made from a steel base with a zinc coating. They are available in lengths ranging from 30 to 150mm and diameters ranging from 2.65 to 6mm.

Top things to consider:

-

Plasterboard nails are available with smooth or ringed shanks. Ring-shanked nails provide a firmer grip than smooth-shanked nails, but they’re better for softwoods rather than hardwoods, where splitting isn’t an issue.

Masonry nails explained

Masonry nails are extremely strong, thick nails designed for joining wood to masonry materials such as brick, mortar, concrete and concrete blocks. They have fluted or grooved shanks, which cause them to rotate as they are being driven so that they can penetrate hard materials. In addition, they're corrosion-resistant so that they can be used outside.

Materials and sizes they’re available in:

Masonry nails are made from bright zinc-plated carbon steel. They’re available in lengths ranging from 25 to 75mm, and diameters ranging from 2.5 to 3mm.

Top things to consider:

-

Masonry nails are available in two shapes, each best suited to different applications. First, round masonry nails are best for concrete work and joining horizontal surfaces. And second, square masonry nails are better for use on brick as their shape reduces the risk of the brick breaking in half.

Collated nails explained

Collated nails are nails that join together on a long strip to be loaded into a nail gun for effortless quick-fire applications. They make carpentry and construction jobs faster, easier, and more efficient. Many kinds of nails are available as collated nails in various sizes and coatings to suit different needs.

Collated nails come under three main categories:

- Framing nails are strong and durable nails commonly used in heavy-duty construction to join timber to timber. They have a pointed tip designed to be driven into wood at speed without causing splitting.

- Finishing nails are small nails with small heads designed to be used in applications where the final appearance is important. For example, to attach mouldings and trims. The small hole they leave can easily be filled in and painted over if the nail is removed.

- Coil nails are nails that are collated into a coil rather than a strip. They’re popular with roofers because they hold enough nails to complete a whole roof without having to reload, but they can be used by other trades too.

Materials and sizes they’re available in:

Collated nails are available in galvanised, stainless steel, and uncoated 'bright' steel materials. Their sizes range from 15 to 90mm in length and diameters of 2.03 to 3.4mm.

Top things to consider:

- For external applications, look for galvanised nails as they are corrosion and rust-resistant.

- Collated nails are often described as being angled or straight. This refers to the type of nail gun they are designed for. Angled nail guns have a longer magazine (the part the nails are loaded into) than straight nail guns. This allows them to accommodate a larger number of nails. So, when buying, ensure the nails are compatible with your nail gun.

Panel pins explained

Panel pins are fine and delicate nails designed for fixing lightweight materials to heavier materials. They are generally used for cabinet and joinery work, such as fixing thin sheet wood to the back of cupboards and wardrobes and fixing skirting. There is also a type of panel pin that has a polymer head. They are used to fix soffits, fascias, roofline trims, etc.

Materials and sizes they’re available in:

Panel pin materials include galvanised, sheradised (similar to galvanised but using a different process), uncoated ‘bright’ steel, and stainless steel. Standard panel pins come in lengths ranging from 15 to 40mm and diameters ranging from 1 to 1.6mm. And polymer-headed panel pins come in lengths ranging from 25 to 50mm and diameters ranging from 3.2 to 6.4mm.

Top things to consider:

-

For extremely delicate work, look for veneer pins. They are a slightly thinner type of panel pin designed for jobs where a panel pin may cause splitting.

Roofing nails explained

Roofing nails are used for roofing applications. They have a short shank and a wide, flat, thin head. And as they’re used outdoors, they’re made from anti-corrosive and rust-resistant materials.

There are two main types:

- Felt nails (or large-head clout nails) are used to fasten roofing felt to timber

- Clout nails (which are shorter and have a smaller head than felt nails) are used to attach slate roofing tiles to metal

Materials and sizes they’re available in:

Roofing nail materials include galvanised, sheradised (similar to galvanised but using a different process) and copper. They’re available in lengths ranging from 13 to 75mm and diameters ranging from 2 to 3.75mm.

Top things to consider:

-

For increased pull-out resistance, look for roofing nails with a ringed shank rather than a smooth shank.

UPVC nails explained

UPVC nails have large-stepped metal heads, fine annular ringed shanks and sharp points. They're used for fixing fascias, soffits and window boards to buildings. The pin heads are available in various colours to match the different shades of UPVC. And they're UV stable, so the coloured heads won't fade.

Materials and sizes they’re available in:

UPVC nails are typically made from stainless steel. They come in lengths ranging from 30 to 65mm and diameters ranging from 2 to 3mm.

Top things to consider:

-

The length of UPVC nails you need will depend on the type of UPVC you are fixing. As a guide, you'll need 65mm nails for fascias, 50mm for cover boards and 40mm for soffits.

Other types of nails and accessories

For large-scale or repetitive nailing tasks, such as laying decking, flooring, roofing, fencing or furniture making, it’s worth considering buying a nail gun. It’s a handheld tool that fires nails into tough materials at the pull of a trigger, vastly reducing the time and effort it takes to do the job manually with a hammer. Nail guns can be powered by mains electricity or air via an air compressor. But if you want a cordless tool that’s easier to move around, choose a gas nail gun powered by a battery and nail gun gas canister.

There are some alternatives to using nails:

- Staples and tacks have a wide range of uses, from upholstery projects and carpet fitting to general construction projects. Most wire staples are fired from a staple gun, but sturdier, galvanised rounded staples are available, which can be hammered into materials.

- Nail-in anchors are permanent masonry fixings that can support light and medium weights, making them ideal for hanging shelves, mirrors and racking straps. They are a two-part fixing consisting of a metal nail inside a nylon anchor. The anchor is installed into a pre-drilled hole, and then the nail is hammered through the object being held, into the anchor.

Safety Equipment When Working With Nails

Using hand and power tools to insert nails comes with risks, so it's essential to consider how to protect yourself. For example, nails are very sharp, nail guns fire nails with considerable force, and driving nails with hammers has risks such as accidentally hitting your hands or the nails shooting off. So, consider wearing PPE such as safety goggles, gloves, and protective clothing where necessary.

Key Considerations When Buying Nails

The information above hopefully gives you a good overview of the different types of nails available and what they can be used for. But here are a few other things to consider before buying:

-

What quantity is needed?

Nails are sold in packs of varying quantities, and the pack size may be indicated by the pack's weight or by the number of nails per pack. Check how many nails you'll need before you buy, as you can often save money by buying larger packs. And if you're a tradesperson who uses nails frequently, buying large packs will save money and time on repeat visits to the store. -

What project are they needed for?

Before buying nails, consider the type of project you need them for. Although some nails are designed for multipurpose use, others are more specialised and are designed for specific applications. Using the right nails for the job will ensure they can take the load they intended to take and stay securely in place. -

What material are they being used with?

It’s essential that the nails you use are compatible with the type of material you are securing, as using the wrong type may cause them to break or work themselves loose. Using the right nails for the material will ensure they provide a tight bond. Also, consider the thickness of the material, as this dictates the length and diameter of the nails needed.