Best drills buying guide

Best drills buying guide

Introduction

A drill is a staple tool for any tradesperson or DIYer’s toolbox. Used to drill holes, tighten or loosen screws, or chisel into materials, it’s a handy tool, useful for multiple projects. But there are many types available, all with different features and functions. So how do you know which is the best drill for your needs?

This comprehensive drill guide tells you everything you need to know about drills. It covers the types of drills available and which ones are best for specific tasks. We look at the different features drills can have and why they are useful. We also explain power ratings and battery technology and highlight some key things to consider when buying a power drill.

What Drill do I Need?

A drill is a toolbox essential that will last for years. So, when you’re deciding which one to buy, there are several factors to consider, such as how often you’ll use it, what drilling tasks you’ll need it for, what type of material you’ll drill into, and your budget.

Some drills are more multipurpose than others, so they can cover a range of tasks. And some also include a screwdriver function. Then some drills are made to suit specific tasks, including powerful drills for drilling into tough materials, drills with longer battery life for extended use, and drills with different features.

Corded or cordless?

The difference between corded drills and cordless drills is how they are powered. A corded drill is plugged into the mains electricity supply, while a cordless drill is powered by a built-in battery.

When deciding which is the best cordless drill, or corded drill for you, consider the pros and cons below:

Corded drill pros:

- The most powerful corded drills are cheaper than their cordless equivalents

- There’s no limit to how long you can use them, making them the best choice for longer tasks

- Most corded drills have two handles, making them ideal for heavy-duty tasks

- They have greater torque and higher speeds than their cordless equivalents

Corded drill cons:

-

Reduced mobility (you need to be near to a plug socket or use an extension lead)

Cordless drill pros:

- They’re convenient

- They give you greater mobility than a corded drill

- They are lighter than corded drills, so they are more comfortable to use for extended periods

Cordless drill cons:

- The most powerful cordless drills are more expensive than their corded equivalents

- The battery life limits how long they can be used each time

- They have less torque and lower speeds than their corded equivalents

What is a brushless drill?

A brushless drill is a drill with a brushless motor. This means it has a motor with an electronic circuit board and sensor to spin the drill shaft instead of the small metal brushes that brushed drills use. This motor reduces friction and heat build-up, increasing its lifespan and making the drill more responsive. It gives better torque control and faster speeds. They are also more energy-efficient and lighter than brushed drills.

Types of Drills

There are many different types of drills available, and we cover the most popular types in the drill guide below. We explain what they are and the types of tasks they’re best used for.

Types of Drills

There are many different types of drills available, and we cover the most popular types in the drill guide below. We explain what they are and the types of tasks they’re best used for.

What is a drill driver?

A drill driver is a multipurpose drill that can be used to drill at high speeds and drive screws into stubborn materials. This is the best drill for home use as it can cope with most small jobs around a house. It’s suitable for drilling into wood, thin metal, and plasterboard, but not masonry.

What is an SDS drill?

An SDS drill is a drill with a Slotted Drive System, which relates to how the drill’s chuck holds and moves the drill bit. The chuck has a piston that fires the drill bit forward and backward in a hammering action. This reduces friction and increases the strength compared to a standard hammer drill. It makes SDS drills ideal for drilling into tough concrete and masonry. In addition, the rotary function can be turned off to allow for chiselling and chasing tasks.

There are three types of SDS drill: regular SDS, SDS Plus, and SDS Max. SDS Plus is simply an improved version of an SDS regular drill, and both types can hold a drill bit with a 10mm shank. They are suited to lighter-duty masonry work and drilling small holes. But the SDS Max can hold a drill bit with an 18mm shank, which can withstand more torque and force. This makes it better for tougher masonry work and drilling large holes.

What is a combi drill?

A combi drill is a drill that combines a drill driver and hammer drill. It’s suitable for tightening and loosening screws, drilling into wood, plasterboard, and metal, as well as drilling into masonry. This makes it an excellent all-rounder drill that allows you to complete a variety of tasks without having to switch between tools.

What is a hammer drill?

A hammer drill is a drill with a chuck that has a hammering action. It uses a mechanism where two sets of toothed gears interact to move the whole chuck backward and forward while also rotating the drill bit. Multiple torque options allow you to adjust the power and keep the rotation speed low, making it suitable for drilling into hard masonry materials without damaging the surface.

What is an impact drill?

The terms impact drill and impact driver are often used interchangeably to describe the same thing – a tool designed to drive in screws rather than drill holes. They have a powerful rotational and downward force, making them ideal screwdrivers for heavy-duty, repetitive, or large screw driving tasks.

What is a percussion drill?

A percussion drill is another type of hammer drill used for drilling into hard materials like concrete and masonry. They are powerful enough for hard materials and have a lightweight frame that makes them easy and comfortable to use for long periods.

Other types of drill

The drills listed above are the most popular types of drills, but some less commonly used drills are designed for more specialised tasks.

For example, a diamond core drill uses a diamond drill bit to drill precisely measured core holes between 8mm to more than 1500mm wide. It’s primarily used to drill concrete, but it’s suitable for most materials, including glass, metal, and tiles.

An angle drill has a short head length at a 90° angle to the grip. It’s designed to fit into hard-to-reach locations and can drill into wood and metal.

Pillar drills are free-standing drills that can be fixed to a table or workbench. Pillar drills are used to drill holes into loose wood or sheets of metal which are placed under the drill. Their ability to drill precise horizontal holes offers better accuracy than a handheld drill.

You may also hear the term ‘twist drill’. But this is a drill bit rather than a drill. It has metal flutes running its entire length, and it’s primarily used to drill into metal, but it can be used for wood and plastic too.

Best Drills For Different Uses

The most important factors to consider when buying a drill are what type of tasks you will use it for and the material you are drilling into.

Here’s a list of the best type of drill to use for the most common drilling applications:

-

Putting up shelves

A drill driver is the best type of drill to use for putting up shelves on a plasterboard or wooden surface. Its drilling function allows you to drill pilot holes, and then you switch to its driver function to put the screws in. However, if you are putting shelves on a masonry wall, use a combi drill (which doubles up as a screwdriver), hammer drill, percussion drill, or an SDS drill for tough masonry. -

Flatpack furniture

Most flatpack furniture is wooden and comes with predrilled holes. So, you’ll only need a drill with a screwdriver action, such as a drill driver or combi drill. -

TV wall brackets

To hang TV wall brackets on a plasterboard or wooden surface, use a drill driver to switch between the drilling and screwing functions. For masonry surfaces, use a combi drill, hammer drill, percussion drill, or an SDS drill for very hard masonry. -

Hanging mirrors or frames

As with shelving and TV wall brackets, the type of drill to use to hang mirrors or frames depends on the material of the surface they are being hung on. For plasterboard or wood, use a drill driver and for masonry, use a combi drill, hammer drill, percussion drill or SDS drill. -

Curtain poles

The wall above window frames can be made of plasterboard, often a metal lintel behind it. So, it’s best to use a drill driver or combi drill, suitable for drilling through metal and plasterboard. -

Best drill for home use

The best drill for home use is the drill driver or combi drill. Both are suitable for drilling into wood, plasterboard, and metal, but choose the combi drill if you need to drill into masonry. They are both excellent all-rounder drills which also have a screwdriver function.

Best drill for chiselling and breaking

An SDS Max drill is the perfect tool for chiselling and breaking up concrete. The rotary function can be switched off, so you can just use its powerful hammer action, and it holds a drill bit with an 18mm shank, which can withstand more torque and force. This makes it better for cutting through tough masonry.

Best Drill by Material

| Material | Recommendation | Best Drill |

|---|---|---|

| Tile or glass | Tiles and glass are prone to chipping and breaking, so using the correct drill and drill bit on these materials is essential. |

|

| Metal | Looking for the best drill for metal? A drill driver is the best drill to use on thin metal. But for thicker metal, use a more powerful combi drill with the hammer action turned off. |

|

| Concrete | Several types of drills can be used to drill concrete. But the best for drilling concrete is a hammer or percussion drill for thin pieces of concrete and a more powerful SDS drill for denser slabs of concrete. |

|

| Wood | The best drill for drilling wood is a drill driver because it can drill at high speeds and drive screws into stubborn materials. |

In addition to using the correct drill for your task, it's also essential that the right drill bit is used. Drill bits come in many forms. There are drill bits to suit the type of material being drilled, drill bits for specific tasks, and drill bits with different shanks (the part that fits into the drill's chuck) to suit different drills. Read our drill bits buying guide for more information.

Drill Features Explained

When buying a drill, there are various features and functions to look out for:

-

Speed

Drill speed tells you how fast a drill rotates, measured in revolutions per minute (RPM). It's also called 'no load speed' because the RPM is the maximum speed the drill turns when not loaded or drilling. The average drill RPM is 1000, but cordless drills can range from 500-2000 RPM, while corded drills can typically operate at up to 3000 RPM. In addition, some drills only have one speed, while others allow you to adjust the speed to suit the task and material you are drilling into. For example, a low speed is better for drilling into soft materials, such as wood, while a high speed is better for masonry materials. -

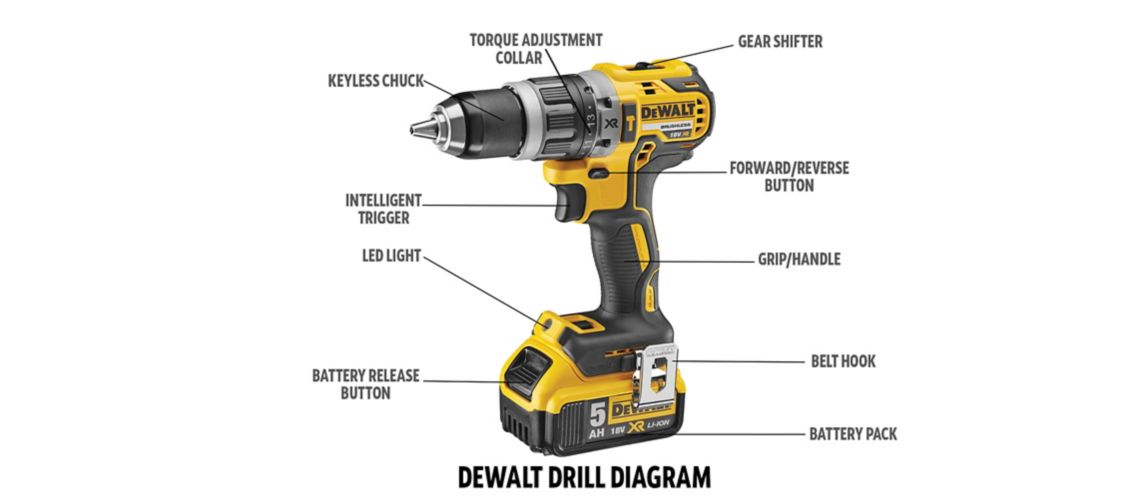

Types of chuck

The chuck is the part of the drill that holds the drill bit or screw bit in place, and it has three jaws that open and close to allow you to put the drill bit in and out. There are several types of chuck available. A keyed chuck uses a separate tool or 'key' to open and close the jaws, whereas to open a keyless chuck, you twist it. SDS drills have a different type of chuck where the drill bit simply pushes in and locks into place. -

Torque control / variable clutch setting

Torque is the twisting force used on a drill that’s required to overcome resistance, measured in Newton metres (Nm). It’s sometimes referred to as a variable clutch setting. Too much torque for a task can result in excess power and loss of control and accuracy. A low torque setting is best for soft materials, while a high setting is better for tough materials like masonry. -

Gears

Gears on a drill allow you to control the speed of rotation. On a drill with one gear, the speed is controlled using the speed control trigger – the harder you push the trigger, the faster the drill rotates. Drills with more than one gear have a gear control button, usually on the top of the drill. This lets you set different speed ranges to fine-tune the amount of power being delivered to suit the task. This gives you greater control and reduces the risk of damaging the surface you are drilling into. -

Forward and reverse function

Some drills only rotate in one forward direction, but some have a reverse function. This allows you to turn the drill bit or screwdriver bit backward as well as forward. It's useful for loosening screws or backing out the drill bit after drilling a hole. -

Depth stop

The depth stop feature on a drill consists of a metal rod protruding out over the top of the drill's chuck and drill bit. Its protrusion can be adjusted in and out to set the depth of the hole you want to drill. Then, as you drill, the metal rod hits the surface you are drilling when you reach your set depth, stopping you from drilling deeper. -

Trigger-activated LED

This feature is ideal if you are drilling in dark conditions. The drill has an LED light built into the chuck. The light switches on to light the work area when the trigger is pulled. -

Auxiliary handle

An auxiliary handle is an extra handle that's positioned on the left or right-hand side of a drill. It helps to improve your force, control, and accuracy when using the drill compared to only holding onto the trigger grip handle. -

Dust extraction

A dust extraction device on a drill is used to vacuum up dust as you drill, so less mess is made, and it prevents you from breathing in harmful particles. This feature is useful when drilling into drywall, ceilings, or masonry. -

Hammer function

mer function on a drill rapidly moves the drill bit forwards and backward while it rotates to increase the drill's force. This function can be found on combi drills, hammer drills, percussion drills, and SDS drills, and it's designed to make drilling into hard masonry materials easier. -

Motor type

Drills can have a brushed or brushless motor. The difference is in the way the drill shaft is spun. A brushed motor uses small metal brushes, while a brushless motor uses an electronic circuit board and sensor. As a result, there is less friction and heat build-up in a brushless motor, giving better torque control and faster speeds. And it also has a longer lifespan than a brushed motor.

Power Ratings Explained

Power ratings on drills are measured differently, depending on how the drill is powered.

Cordless drills are powered by a battery, so their power is measured in volts. They can range from 7.2V to 54V. A corded electric drill's power is measured in watts ranging from 450W to 1900W.

The power rating on a drill is important because the higher the voltage or wattage is, the more power the drill has, and therefore it can tackle heavier tasks. So, for example, you'll need significantly more power to drill into concrete than you would to drill into soft wood.

Battery Technology

Cordless drills are powered by built-in rechargeable batteries. There are three types of technology: Nickel-Cadium (NiCad), Nickel-Metal Hydride (NiMH) and Lithium-ion (Li-ion).

NiCad batteries are the oldest technology of the three. These batteries are cheaper than the other types, but they have a good life span if they are well maintained. In addition, they are tough and resistant to impact and extreme temperatures, so they are ideal for outdoor use. On the downside, they are heavy, so they aren't comfortable for prolonged use, and they run out faster than other battery types. Ideally, the battery should never drop below 70% charge, other than once a month, when it should be fully discharged. Otherwise, their memory is severely affected, and their lifespan is diminished. They also need to be given time to cool down before being charged, which increases their charging time.

NiMH batteries are more expensive than NiCAD, but their capacity is often 2 or 3 times greater, and they weigh less. On the downside, they have a rapid self-discharge and are sensitive to extreme temperatures. And, like NiCad batteries, they need to be kept at 70% charge, with a full discharge once a month to maintain them. But, if they’re left fully discharged for long periods, the battery will deteriorate rapidly, and its lifespan will be significantly shortened.

Lithium-ion batteries are used in most cordless drills. They can be charged at any time, no matter what charge percentage they already have. They also have no self-discharge, so they won't drain unless you're using them. So, even if you don't use the drill for a long time, it will be ready to use the next time you need it. In addition, Li-ion batteries charge from empty to full power quickly – typically within 60 minutes and hold more power for longer than other battery types. Another advantage is that they're lightweight, making drills with this battery type comfortable to use for long periods. And they're better for the environment.

Key Considerations When Buying a Power Drill

-

Do you need a screw driving function?

If you regularly need to drive screws into the holes you've drilled, it's worth having a drill that doubles up as an electric screwdriver. It will make your work much quicker. So, choose a drill driver or, if you need to drill into masonry too, a combi drill. Also, consider buying one with variable speed, torque control, and a reverse function, so you can remove screws as well as insert them. -

How frequently and for what period of time will you use the drill?

This is important to consider if you plan to use the drill for long periods. Choose a drill with an ergonomic design so the handle is comfortable to hold. Also, if you're considering a cordless drill, consider the battery weight, as holding a heavy battery will be tiring. -

What is the battery life?

If you've decided on a cordless drill, check the battery capacity to determine how long it will run on a full charge. Battery capacity is measured in amp hours (Ah), and the number tells you how many amps of electrical charge the battery can deliver in one hour. The higher the number, the longer you can use the drill before it runs out. -

Does it have the drill bits that you need?

Most drills are sold without drill bits, so they must be purchased separately. But before buying the drill, if you know there are specific drill bits you want to use for a specialist task, check that the drill can take those drill bits. -

What materials will the drill be used on?

This is probably the most crucial question to ask yourself before buying a drill. Most drills will drill into most materials, except for masonry. To drill into masonry, you will need a drill with hammer action, such as a combi drill, hammer drill, percussion drill or SDS drill. The material will also be a deciding factor when looking at speed, gears and torque control. For example, to drill large holes in masonry, you'll need a low-speed gear. And you'll need variable speeds and torque to drill into a variety of materials, so they can be adjusted accordingly. -

What functionality will be required?

Consider which features will be beneficial for you before buying a drill. Variable speed, gears, and torque are recommended if the drill will be used with a variety of materials. The hammer action is required for masonry drilling. Dust extraction is ideal if you regularly drill into materials that create a lot of dust. And an auxiliary handle, depth control, and LED light are all useful for precision drilling.